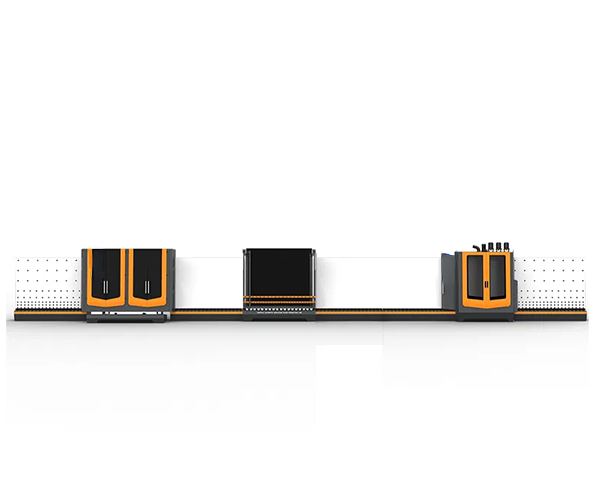

Description

Technical parameter

- Processing glass size: minimum 400 mm * 300 mm, maximum 3000 mm * 2500 mm (length*height)

- Output: 110 pieces/hour

- Original glass thickness: 3-12 mm

- Thickness of processing insulating glass: maximum 50 mm

- Power supply: 380 v, 50 Hz

- Total power: 44.3 Kw (including heating power 16 kw)

- Working direction: the right to left is the positive direction – the operator faces the front of the device (the direction can be requested by the user).

- Working speed: cleaning speed: 3-9 m/min, transmission speed after cleaning: 15-45 m/min

- Dimensions: 24000 mm * 2500 mm * 3680 mm

- Total weight: 9500 Kgs

Main performance features

1. Identification of Low-E coated glass

It can identify the film layer of the coated glass, ensure the correct position of the film surface, and avoid unqualified products caused by the wrong position of the film surface.

2. To ensure that the coating layer is not scratched when making the coated insulating glass, three sets of soft brushes are used to work at the same time; the cleaning and drying section shield and the wheel frame are all made of food-grade 404# stainless steel, and the parts in contact with water are made of Stainless steel and other corrosion-resistant materials; high-pressure fans, sealed sound-absorbing materials and circulating air devices not only reduce secondary pollution but also reduce energy consumption and noise, ensuring long-term optimal cleaning effect and service life. The shell of the washing machine is made of stainless steel, and the upper and lower top plates are made of 5 mm thick stainless steel plates.

3. Increase the transmission section, and greatly improve the work efficiency

The conveying section is increased to two sections, which can store more glass after cleaning, avoiding the production bottleneck caused by the slow cleaning speed, and thereby improving production efficiency.

4. Energy-saving intermittent automatic work

When the glass runs to the end of the lamp inspection section and stops, the brush and the water pump also stop working, the fan damper is closed and the power is reduced to a minimum. After the front glass is assembled, the brush, water pump, and fan will automatically return to normal work.

5. Reasonable aluminum strip positioning design

The glass is stopped and positioned at the end of the positioning section of the aluminum frame, that is, the aluminum bars are placed. The side positioning and lower positioning of the aluminum frame are manually and steplessly adjustable, and the scale is displayed, which is convenient for adjustment. In addition, while the glass on the segment is automatically combined, aluminum bars can be placed in the positioning segment of the aluminum frame, which greatly reduces the average production time of each piece of glass and improves production efficiency.

6. Automatic detection of glass height

The segmented lifting beam is equipped with a glass detection device, which always stops at a position 10cm above the glass, without having to go up and down every time, which greatly improves the speed of splicing. The positioning of the second piece of glass on the combined segment is accurate, and it is completed by the manipulator, which does not require manual push to assist with the positioning, and truly realizes the automatic combination.

7. Externally combined double insulating glass

According to production needs, in addition to making single-layer insulating glass, it can also automatically combine double-layer insulating glass in the splicing segment to meet market demand and increase market competitiveness.

8. Secondary plate pressing

When the length of the glass is greater than the length of the plate pressing section, secondary pressing can be performed. The plate pressing surface can be fine-tuned.

9. After the plate pressing section is a vertical conveying section

After the plate is pressed, the next section is a vertical conveying section, which is convenient to connect with the automatic gluing machine and improve the automation degree of the equipment.

10. Touch screen monitoring and display system, automatic diagnosis of equipment failure

Equipped with a 10.4-inch touch screen man-machine interface, it can automatically display the production process of insulating glass and the operation of the equipment, and automatically diagnose equipment failures. The system is set with a pause function. When there is a problem with the glass, press the emergency stop button, put the glass in its original position after processing it, turn on the emergency stop button, and press the reset button, and the system will return to its original working state. Improve work efficiency and reduce labor intensity.

The Air-floating Glass Transmission Section

At present, with the development of technology and market demand, the insulating glass format of glass curtain wall buildings continues to expand and its thickness continues to become thinner. Therefore, the production technology of the insulating glass automated production line is required to be higher. At present, large-sized hollow front flat glass is mostly transported by contact transmission rollers. These contact methods can easily cause scratches and contamination to the flat glass, and can easily cause the glass to break, thus seriously affecting the quality of the product and thus the production efficiency.

Reviews

There are no reviews yet.