Description

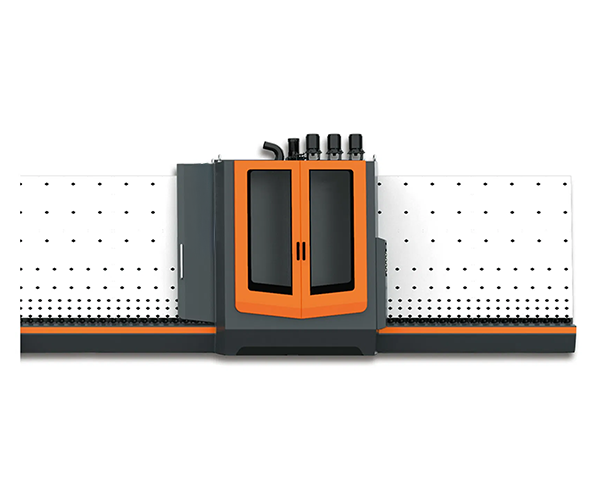

The DoorMach Glass Automatic Vertical Glass Washing and Drying Machine, which is equiped with the steel structure, and protective cover are all made of high-quality stainless steel. It is divided into glass washing and drying sections by conveying rollers, cylindrical brushes (the brush material is made of high-temperature resistant nylon wire) driving devices, water spray pipes, and water supply system, wiper blade, air knife air filter, silencer device, etc.

- Three pairs of cylindrical brushes are independently driven by three asynchronous motors. The first and second pairs of brushes are pre-washed. The third pair of brushes can be cleaned with deionized water and sprayed with deionized water on the glass (three brushes and four showers), water treatment optional) high-pressure water nozzle is removable for washing and easy to maintain.

- The brush could wash different thicknesses and types of glass (Low-E glass is optional).

- Automatic tensioning and compression of the transfer roller, automatic adjustment for washing glass of different thicknesses, using waterproof bearings, and parts in contact with water are made of stainless steel, aluminum, or copper, with long service life; there is a piece of soft material scraper on the upper and lower sides of the glass at the end of the washing section The water plate and the glass pass between the two wiper blades.

- Washing water can be recycled. The water tank has a water heating device that can heat the water. Use water with a temperature of about 50°C to wash the glass for better results.

- The unique air knife design uses a pair of stainless steel inclined air knives made by CNC bending technology to form a high-pressure air filter. The pressurized air is connected to the air knife edge through the hose, and the dry air is blown from the air knife edge at an optimal angle. The glass pieces are washing and the drying effect is good.

- Inside the blower, the drying section is equipped with sound-absorbing materials.

Equipment Advantages

glass washing machine can wash max glass of 2500 mm*3500 mm, more large size and less size can be optional.

– Self-Diagnosis system with touch screen on computer.

– Fully corrosion-resistant materials, including the air knife and brush roller are made of stainless steel.

– Stainless steel washer with 8 ( could optional 6 ) brushes, soft brushes from MONFORTS of Germany, hard brushes automatically open when Low-E glass input.

– Rotate speed of brush frequency control. (optional)

– Stainless steel air knife is automatically adjustable according to glass thickness, Max thickness to 19 mm.

– High speed washing ( max 14 m/min), Low noise ( max 70 dB), high availability working. (25 second /unit)

– Automatic detection of Low-E glass and alarm for coating in reverse. (optional)

– Structure stepped and three-layer insulating glass unit available. (optional)

– Precision of plate press: ±0.3mm.

– Two relatively independent water tanks. Water can only flow from the rear water tank to the front water tank.

The water tank is equipped with a heater; 3 pairs of brushes (high-temperature wire) and four pairs of water spray pipe structures. The water channels of each brush are sealed to prevent the washing machine from being damaged. Internal sputter contamination.

Advantages & Benefits

☆The glass washing machine could wash ordinary flat glass or coated glass with a thickness of 3~12mm;

☆The washing area uses 3 pairs of brushes or optional 4 pairs of brushes (or imported soft brushes, coating or Low-E Glass special), two or four water cleaning;

☆The machine adopts an inclined vertical structure, the flat glass is placed on the conveyor roller, passes through the feeding section, cleaning and drying section, and reaching the discharging section to complete the glass cleaning task;

☆The washing area and the water tank are made of stainless steel and corrosion-resistant materials; the inclined wind knife with strong wind can dry the glass surface;

☆The discharge section is equipped with inspection lamps to check the cleaning quality of the glass. The machine is easy to operate, and the operation buttons are concentrated on the operating table.

Configuration of three pairs of brushes

Six high temperature resistant wire brushes with diameter of 180mm + four sprays, the glass is cleaned and the speed is fast (10-12m per minute). The first brush is equipped with two bristles and is lifted by a cylinder.

Water rust and corrosion resistant

The parts and screws in the washing box that are in contact with water are made of stainless steel, copper, waterproof aluminum, nylon and other materials. They will not rust after long-term use and are easy to maintain.

High efficiency air knives

Two pairs of stainless steel air knives are equipped with high wind power and good drying effect, with heating system. The unique circulating windshield drying system is energy-saving and low-noise (the wind temperature can reach 40 degrees without heating in winter).

Stainless steel structure

The air-drying box glass support frame is uniformly welded by high-strength stainless steel, and the whole washing parts of glass washing and drying equipment will be used for a long time without rust and will not cause secondary glass pollution.

Reviews

There are no reviews yet.