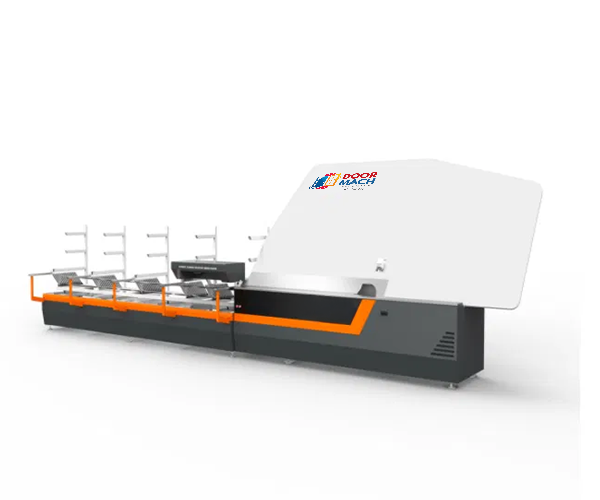

Description

The angled aluminum frame is one of the reasons for the poor sealing of insulating glass;

the main reason for the failure of angled insulating glass in the case of double sealing is usually improper handling of the four corners of the aluminum frame. Affects the sealing effect of insulating glass. With the improvement of corporate quality awareness and market competition, more and more companies are using aluminum strip bending machines to produce overall bent aluminum frames. In addition to fully automating the aluminum strip bending machine, glass deep processing practitioners use computers to input the shape, input size, input production quantity, input glue amount, etc. to the aluminum strip bending machine, as well as realize functions such as automatic splicing of aluminum strips, and innovate aluminum strips. The use functions of the bending machine are also placed in front of aluminum strip bending machine manufacturers.

It can be realized by bending the whole aluminum strip;

1. Install an argon gas filling hole on the aluminum strip bending machine.

Filling the insulating glass with argon gas is necessary for insulating glass buildings to save energy, reduce noise, lower the dew point, prevent the deformation of the insulating glass from causing the two pieces of glass to stick together, and prevent the oxidation of Low-E glass. As the number of companies that directly inflate air on insulating glass lines increases, the demand for companies that inflate air on aluminum frames is also increasing. This function can be added to the newly developed aluminum strip bending machine. Using an aluminum strip bending machine to drill air holes greatly improves the efficiency of drilling holes in the aluminum frame.

2. Add the digital dimensioning function to the aluminum strip bending machine.

Nowadays, insulating glass production continues to be concentrated in large-scale insulating glass production enterprises. In large-scale production enterprises, insulating glass aluminum frames with similar sizes are prone to confusion when making insulating glass, and the accurate size cannot be found. As a result, the company’s production is chaotic and quality is difficult to guarantee. When the aluminum strip bending machine bends the aluminum frame, printing the size and production date of the aluminum frame on the aluminum frame can avoid such problems and improve production efficiency. In addition, to completely solve the problem of aluminum strips affecting the sealing of insulating glass, special equipment for molecular sieve filling and aluminum strips is needed.

2. Introduction to supporting equipment for fully foldable aluminum frames.

Fully folded aluminum frame equipment includes a semi-automatic molecular sieve filling machine, automatic molecular sieve filling machine, semi-automatic aluminum strip bending machine, and fully automatic aluminum strip bending machine. The semi-automatic molecular sieve filling machine can punch the molecular sieve filling holes and fill the molecular sieve. In addition to flushing and filling molecular sieve holes, the fully automatic molecular sieve-filling machine can also automatically seal the molecular sieve-filling holes with glue. A semi-automatic aluminum strip bending machine can fold aluminum strips into rectangular shapes. In addition to folding aluminum bars into rectangles, the fully automatic aluminum bar bending machine can also bend aluminum bars into circular arcs and other arbitrary shapes.

Benefits & Advantages

- Germany Siemens PLC control system

- Germany Siemens CNC servo control system

- Four spacer size storage units

- CNC servo control feeding mechanism

- Auto furnishing and cutting spacer fuction

- Auxiliary function of adjustment for bending Large aluminum frame

- Can be optional to different specifications and sizes of aluminum space

- Supporting bending for different shapes’ spacers Continuously

- Separated guard board outside of bender

- Automatically avoid the connection while bending and cutting

- Pause/set device, convenient for machine malfunction maintenance, protect the servo motor

- USB input function, read the excel format file directly etc(optional)

- Spacer printing function(Optional)

- Can bend aluminum spacer, Technoform, Alupro, Thermix, Swisspacer and Stainless steel(Stainless steel optional)

- Automatic drill gass filling hole(Optional)

Technical Data

| Item. | Spec. |

| Dimension | 10500mm*2200mm*2600mm |

| Max.bending size | 2000mm*2000mm (2500mm*2500mm) |

| Min.bending size | 250mm*200mm |

| Aluminum spacer width | 5.5-27mm |

| Dimensional error | ±0.5mm |

| Angle error | ±1º |

| Processing speed | 0-47m/min |

| Air pressure | ≥0.65MPa |

| Total power | AC220/380V 50Hz 2.5Kw |

| Weight | 1800kg |

| Production capacity | 90m/min |

Operating Procedures

- Check whether the equipment and working area are cleaned and wiped clean; there should be no obstacles, impurities, new pulls, grinding, or bruises on the equipment bed, work surface, guide rails, and other main sliding surfaces. If any of the above situations occur, the equipment must be cleared and the equipment must be wiped clean; if new pulls, grinding, or bruises occur, the person in charge of the equipment or the team leader should be asked to check together and make a record.

- Check that the handles, valves, and major components of each operating mechanism should be placed in non-working positions.

- Check that all safety protection devices (protective cover, limit switch, limit stop iron, electrical grounding, safety device, etc.) are complete and intact, and installed correctly and reliably; the door covers of distribution boxes and oil pools should be closed.

- Check that the amount of oil in the lubrication parts (oil pool, oil cup guide rail, and other sliding surfaces) is sufficient, and add oil according to the lubrication instruction chart.

- Check whether the main components and fasteners are abnormally loose. Aluminum bar bending machine operating procedures

- Carry out a dry running test run, start with inching, and check that each operating device, safety device (braking, reversing, interlocking, limit, insurance, etc.) and each indicating device (indicating instrument, indicator light, etc.) should work sensitively, accurate and reliable; the movements of all parts should be coordinated; the oil supply should be normal and the lubrication should be good; the machine tool should operate without abnormal sounds, vibrations, temperature rises, odors, smoke, etc. Make sure everything is normal before starting work.

Reviews

There are no reviews yet.