Description

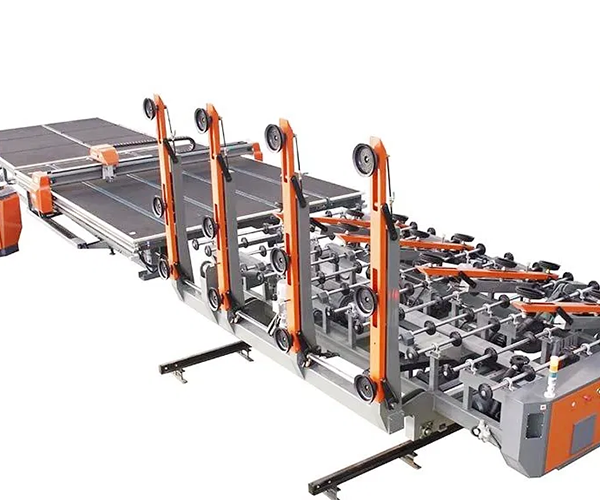

Equipment Overview

1. Motion controller

1) The movement speed is fast, the action is stable, the control precision is high, and the controller is modularized.

2) The human-machine interface is simple and elegant, and parameter adjustment is simple.

3) Photoelectric positioning cutting mode, direct cutting mode, oil-free cutting mode, automatic/blank mode switching can be realized at any time during glass processing.

4) Library nesting programming, select the special shape from the library, set the relevant parameters, and the glass processing quantity can be directly nested and cut.

5) The complete glass pressure library is stored, and the cutting pressure of various thicknesses can be input and saved at one time, and can be called directly next time.

6) Real-time tracking and display of processing path, timely recording of motion coordinates, axis status, I/O status, fault diagnosis and automatic alarm recording.

7) It supports a variety of processing file types, accepts standard G codes of nesting software such as Optima and Guiyou, and DXF format files of AUTOCAD. The graphics editing software that comes with the system can adjust the direction of the tool path and delete line segments.

8) Various protections: including soft limit, cutting limit, external emergency stop, etc.

2. Optimize the software

1) The optimization results done in the office can be imported, and the optimization in the office in advance can save time and improve efficiency.

2) The cutting order can be manually edited

3) A variety of glass original sheets and small sheets can be optimized at the same time

4) Optimized typesetting without size limitation, optimized results, rotation and mirror management and other practical functions

5) Priority management for optimization of cutting small pieces of glass

6) Priority management of glass original sheet optimization

7) Original glass inventory management

8) A variety of efficient optimization algorithms

9) Cutting graphics can be edited

10) Label design and label printing

11) The optimization result report is clearly printed

12) Supports the import of Excel data files

13) The special-shaped glass cutting library contains more than 350 parametric graphics, including all commonly used graphics for glass cutting.

14) Software operation with multiple language options

Equipment Configuration

| Object / Parts Name | Manufacturer Brand / Trademark |

| Optimization Software | Optima |

| Cutting Software | EOS-NC |

| Servo Motor | YASKAWA |

| Proportional Electromagnetic | SMC |

| Inverter | Delta |

| Touch Panel | Delta |

| Programmable Controller | Delta |

| Photoelectric Switch | Otonmic / Mibo |

| Proximity Switch | Mibo |

| Middle Relay | IDEC |

| Motor Circuit Breaker | Schneider |

| AC Contactor | Schneider |

| Gear Motor | BFL |

| Air Cylinder | XingYu |

| Bearing | NSK / HRB |

| Spline and Gear | Lead Rack |

| Bezel Panel | Density Doard |

| Table Board | Industrial Blankets |

| Centrifugal Fan | SN |

Reviews

There are no reviews yet.