Description

This high-precision 3+1 axis CNC machining center is engineered for the versatile processing of aluminum, UPVC, copper, and alu-wood composite profiles. Featuring advanced multi-angle capability, it allows for milling, drilling, chamfering, and slotting at any angle between -90°, 0°, and +90° in a single clamping setup.

1. Robust Structure & Precision Mechanics

-

Heavy-Duty Monoblock Frame: The machine body utilizes a high-strength welded steel structure. It undergoes a critical thermal annealing (stress-relieving) process to eliminate internal stress, guaranteeing permanent rigidity and preventing deformation over the machine’s lifespan.

-

Premium Motion System: The X, Y, and Z axes are driven by imported high-precision linear guideways, ball screws, and helical gear racks. Powered by high-torque servo motors, this transmission system ensures smooth acceleration and micron-level positioning accuracy.

2. High-Speed Spindle & Tooling

-

Motorized Spindle: The machine is equipped with a high-quality imported high-speed spindle. It is balanced for low noise and vibration, ensuring exceptional cutting ability and superior surface finishes.

-

Automatic Tool Changer (ATC): An integrated 8-station tool magazine allows for rapid, automatic tool changes during the program. This enables the machine to perform multiple complex operations (e.g., drilling followed by tapping) without manual intervention.

3. Productivity & Efficiency

-

Dual-Zone (Pendulum) Processing: The worktable features a “double zone” design. This allows the operator to load/unload profiles in one zone while the machine is actively cutting in the other (interactive feeding). This non-interference design eliminates idle time and maximizes throughput.

-

Versatile Machining: Capable of handling complex geometries on various light alloys and composites, making it ideal for window, door, and curtain wall fabrication.

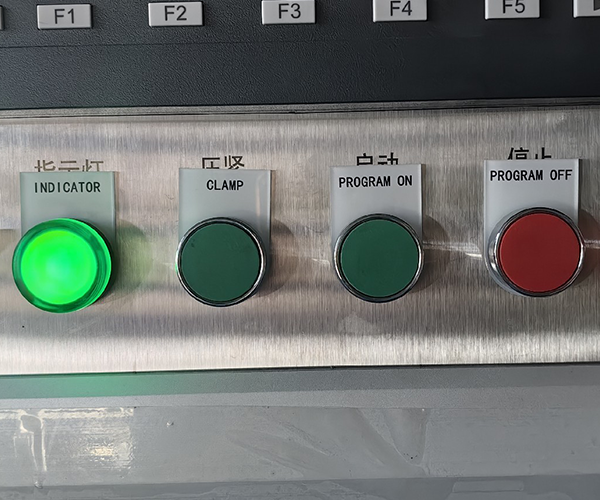

4. Control & Safety

-

Advanced CNC Interface: The system runs on an industrial-grade numerical control platform with a user-friendly Human-Machine Interface (HMI). It offers simple operation, reliable performance, and easy programming.

-

Full Safety Enclosure: The machine is completely enclosed to ensure operator safety during high-speed machining.

-

Chip Management: Equipped with an automatic bottom chip collection device, the design promotes a clean, environmentally friendly workspace.

| Parameter: | |

| X-axis stroke | 3200mm |

| X-axis feed rate | 0~80m/min |

| X-axis positioning accuracy | ±0.05mm |

| Y-axis stroke | 200mm |

| Y-axis feed rate | 0~20m/min |

| Y-axis positioning accuracy | ±0.05mm |

| Z-axis stroke | 180mm |

| Z-axis feed rate | 0~20m/min |

| Z-axis positioning accuracy | ±0.02mm |

| Z-axis positioning accuracy | ±0.02mm |

| Power Specification | 380V/50Hz Customized |

| Total Power of Machine | 6.5kW |

| Machine Size | 3500x1830x2250mm |

| Repeat location accuracy | ±0.02mm |

| Roughness | Ra 6.3 um |

| Spindle Power | 3.5kW |

| Spindle Speed | 0~18000rpm |

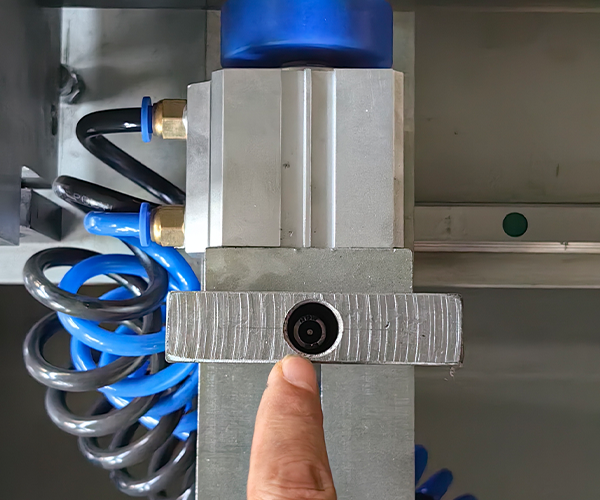

| Working Pressure | 0.6~0.8MPa |

| Weight | 1800 |

| 3 Axis travel Range | 3200*530*410 |

Reviews

There are no reviews yet.